Leather can be classified into various categories based on factors such as how it is cut, its quality, grading, finish, and the type of animal it comes from. Other classifications include leather with fur, as well as synthetic alternatives like faux and vegan leather. Each type has distinct characteristics and differs significantly in texture, durability, and appearance.

Some differences arise from the way leather is manufactured. Some are due to the finishing process. Some variations depend on the type of animal hide, while others are determined by how the leather is cut. We will examine each of these aspects more thoroughly.

Types of Leather

There are many types of leather, but people often refer to the “five main types.” This classification is based on how much of the original hide remains intact in the final product. These types include full-grain, top-grain, genuine, split-grain, and bonded leather, each with its own unique properties and characteristics.

The quality and features of leather depend on which part of the hide it comes from. Several factors influence its durability and texture, including the breed of the animal, the climate it lived in, its diet, and its level of physical activity. Since leather is a natural material, it reflects the conditions of the animal’s life.

In addition to these natural factors, the quality of leather is also shaped by the processes used in its production, such as meatpacking, tanning, and finishing. Along with the commonly recognized leather grades, professional tanners have their own grading systems to assess hides received from meatpackers before they are processed further.

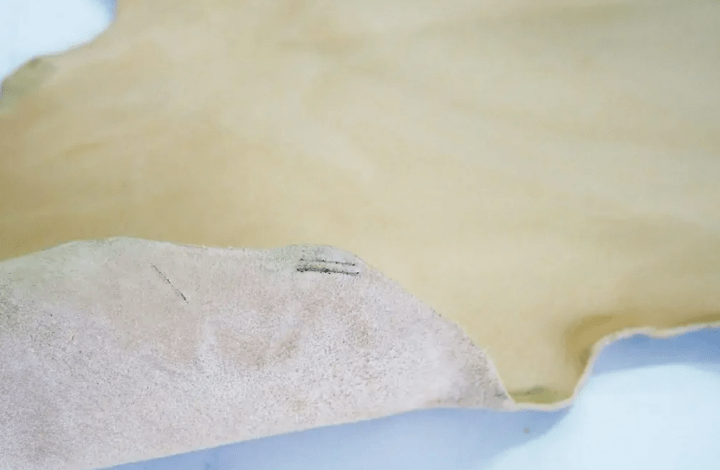

What is Leather Hide

Great! Let’s start here. A leather hide refers to the outer skin taken from an animal. As a naturally occurring material, it possesses distinct features and properties that originally served to protect the animal it belonged to.

It usually forms a protective barrier. This serves as a protective barrier for the animal’s internal organs. Along with hair or fur, it helps shield against external factors like sunlight, moisture, abrasions, and other environmental influences encountered in daily life. Below is a cross-section illustration depicting the different layers of a leather hide.

Leather Hide- The Grain

The grain refers to the outermost layer of the leather hide. It is comprised of tight, dense fibers. This part of the hide was exposed to natural elements such as air, rain, and sunlight. Once the hair is removed, the grain typically becomes smooth and remains one of the strongest sections of the leather.

Leather Hide – The Grain and Corium Junction

The point where the grain layer meets the corium is where the dense, outer surface transitions into the looser, more fibrous structure of the corium. This area contains a combination of the strong, desirable grain layer and the softer, more open fibers of the corium.

Leather Hide – Corium

The corium is a section of an animal hide primarily made up of collagen fibers, which are more loosely arranged compared to those in the grain layer. Despite its softer structure, this layer is widely used in leather production. It is also typically the thickest part of the hide. When a hide is split, portions of the corium can be found in both top-grain and genuine leather products.

Leather Hide – Flesh

When evaluating leather grades and quality, it’s important to consider how the leather is processed, cut, and finished. Let’s explore the most common techniques used in leather production.

TYPES OF LEATHER GRADES AND LEATHER QUALITIES

These are the most widely recognized methods for categorizing leather. In reality, these terms are more related to how the leather is split and how its surface is treated, rather than indicating true “grades.” However, these factors do influence the performance and overall quality of the leather product.

As a result, people often refer to them as different “grades of leather.” Following this, we’ll look at the actual grading systems that meatpackers use when assessing hides for sale to tanneries.

Full Grain Leather

This type of leather includes the topmost layer of the hide, known as the “grain.” It has not been sanded or buffed to smooth out any natural imperfections. Typically, only the hair is removed in full-grain leather. The grain is composed of tightly packed fibers, which results in a surface that is exceptionally strong, durable, and able to endure heavy use.

Because the surface is left untouched, it may feature minor imperfections. These could include marks from where the animal brushed against a fence, small cuts, or scratches from daily activities. Full-grain hides with few blemishes are highly valued, as they are rarer and often considered the most visually striking.

The dense fibers in the outer layer provide the leather with its superior strength, making it ideal for products like saddlery, footwear, and furniture. As the leather ages, it develops a patina—a natural color change that enhances its appearance. Additionally, the outer layer offers some resistance to water. Full-grain leather is often considered the finest quality leather due to its durability and natural characteristics.

Top Grain Leather

This cut is quite similar to full-grain leather, but it undergoes a process where the top layer is sanded or buffed to eliminate imperfections and uneven areas in the surface. As a result, the leather becomes softer and more flexible, with various dyes and finishes applied to enhance its appearance.

While this sanding process improves the visual appeal of the leather, it also diminishes some of its strength and water-resistant properties that are inherent in full-grain leather. This highlights the tradeoff between leather durability and its aesthetic appeal and softness.

Due to its smooth texture and flexibility, top-grain leather is commonly used in luxury leather products, such as handbags, wallets, and shoes.

Genuine Leather (Corrected Leather)

Genuine leather can be made from any part of the hide and typically undergoes treatments to create a smoother, more consistent surface. This process may involve sanding or buffing to eliminate any imperfections, followed by dyeing (or spray painting) or applying stamps and embossing for texture and design.

Though these treatments may compromise some of the natural qualities of the leather, genuine leather is commonly used in products like belts and similar items, where durability and appearance are important but top-tier quality is not required.

Split Grain Leather

Split grain leather is derived from the lower layers of the hide, specifically from the section just beneath the top grain but above the flesh. It sits between the full grain and top grain cuts, making it a more affordable option compared to the higher-quality leather types. Though, it still provides a useful leather material.

The natural texture of split-grain leather is not as dense or tightly structured as full-grain or top-grain leather. As a result, it is commonly used for leather finishes that involve coloring, embossing, or significant surface modifications. This makes it possible to retain some of the beneficial qualities of leather while offering an aesthetically appealing and often practical surface for various leather products.

Bonded Leather (Reconstituted Leather)

Bonded leather is often compared to a synthetic leather product made from leftover leather scraps, which are shredded and fused together using a binding agent like polyurethane or latex. These bonded pieces are then applied to a fiber mesh or sheet. The proportion of actual leather within the mixture can vary widely, ranging from as little as 10% to as much as 90%, which directly impacts the overall quality, durability, and appearance of the final product.

To enhance its visual appeal, bonded leather is frequently dyed to achieve the desired color and may be pressed or embossed to mimic the texture and grain pattern of more expensive leather types.

TYPES OF LEATHER GRADES- FOR RAW HIDES

When raw hides are produced by meatpackers, they immediately grade them. This grade is used to determine the quality of the raw hide, and enables accurate sales to tanneries. The tanneries will ultimately tan the hides, processing the raw material into a finished leather.

As such, it’s important to know exactly the qualities of leather they are receiving. This ensures they’ll have what’s needed to consistently produce quality finished leathers for the production of leather goods.

When grading raw hides, the inspectors will look for issues including holes, deep cuts, scars, large abrasions, discolorations, machine damage (from the skinning machines), remaining hair, and grain inconsistencies.

It is important to keep in mind, too, that many large ranch operations brand their cattle to denote ownership. Branding involves permanently burning a unique pattern (usually letters or initials) into the skin of the animal. A metal brand in the form of the pattern is heated, then pressed into the animal to leave the pattern permanently burned into the hide. While common, the brand impact to the hide quality is also accounted for in the grading process.

The hides will generally be graded as follows:

Leather Hide Grade – Number One

Number one hides are top grade hides. They generally have no major surface imperfections, holes, or cuts. If there are holes approximately 3-4 inches from the edge of the hides, and they can be trimmed away, they won’t affect the overall grade. About 80% of hides shipped to tanners should be a number one grade.

Leather Hide Grade – Number Two

A number two hide is allowed to have up to four holes or cuts, as long as they are located in a generally straight line on the hide. This would allow them to be cut around later, still yielding a sizable area of usable hide.

Holes should usually be less than 5” to be considered acceptable within a number two grade hide. Grain defects should also be no larger than approximately 1 ft. sq. in coverage area. Approximately 15%-20% of hides shipped to tanners have a number two hide grade.

Leather Hide Grade – Number Three

Number three hides generally have five or more holes or large cuts within the hide, ideally within a generally straight line. This would allow them to be cut around later, still yielding a sizable area of usable hide.

A single cut or hole over 6” can be allowed. There might also be grain defects, or a series of closely-located smaller holes that comprise a surface area larger than 1 ft. sq. In general, number three graded hides should at least yield a 50% usable surface area.

Generally, number three grade hides are only purchased by tanners when they have specifically agreed to purchase this grade of hide.

Leather Hide Grade – Untannable

Hides that do not meet the quality standards of grades number one, two, or three are deemed untannable. They are not shipped to tanners, and enter another viable channel for use of the raw animal hide materials, outside of the leather industry.

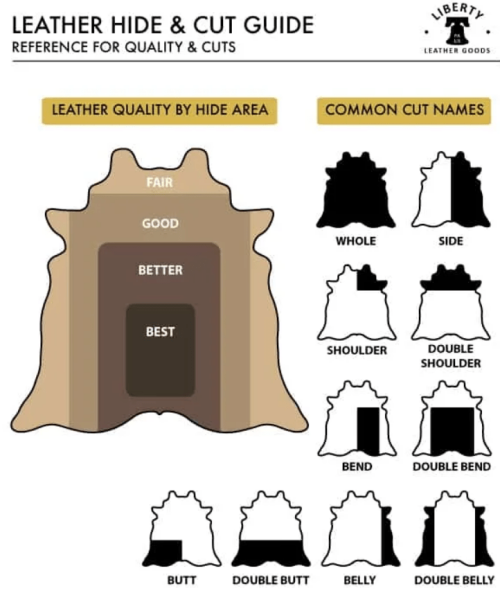

TYPES OF LEATHER CUTS

A finished leather hide has a fairly large amount of leather to choose from when deciding where to cut from the use pieces on a project. Based on the area of the hide in relation to the animal’s body, some pieces will be a little higher quality and a little easier to work with.

Finished leather can usually be purchased based on cut type. This can include the full hide, or specific areas within it. Based on the type of project you are working on and the performance characteristics you want in the finished piece, it can be helpful to know what the different available cuts are.

Whole Leather Cut

A whole leather hide encompasses the entire skinned and tanned hide from an animal. Since it includes the areas from all of the other related cuts, the leather available will range from softer areas with various stretch characteristics, to thicker, stiffer areas of the hide. The range of leather thickness and weight will vary across the entire hide.

Side Leather Cut

The side cut of a leather hide is a half of an entire hide, cut lengthwise along the middle. since this includes at least parts of areas from all related cuts, the leather available will range from softer areas with various stretch characteristics, to thicker, stiffer areas of the hide.

Shoulder Leather Cut

The shoulder cut of a leather hide comes from the shoulder area of the animals. This area generally has a firm, yet malleable and flexible feel to it. Shoulder cuts work well for tooling.

Double Shoulder Leather Cut

The double shoulder cut of a leather hide comes from the shoulder area of the animals. It is essentially the entire shoulder area from the hide. This area generally has a firm, yet malleable and flexible feel to it. Shoulder cuts work well for tooling.

Bend Leather Cut

The bend cut of a leather hide is from the area ranging from the spine towards the belly, towards the middle of the hide. This is some of the best leather available in a hide, the prime sections generally towards the hind side before the butt. It is best used for across a number of leather product applications.

Double Bend Leather Cut

The double bend cut of a leather hide is from the area ranging from the spine towards the belly, towards the middle of the hide. This is some of the best leather available in a hide, the prime sections generally towards the hind side before the butt. It is best used for across a number of leather product applications.

Butt Leather Cut

The butt cut of a leather hide is from the hind leg portion of the hide, running around the butt and up towards the spine. This is the thickest and firmest area of the hide. Butt cuts make a good leather for thicker items such as heavy belts.

Double Butt Leather Cut

The double butt cut of a leather hide is from the hind leg portion of the hide, running around the butt and up towards the spine, on both sides of the hide. This is the thickest and firmest area of the hide. Butt cuts make a good leather for thicker items such as heavy belts.

Belly Leather Cut

The belly cut of a leather hide is from the left or right edges of the hide. The belly of animals naturally expands and contracts as food and water are consumed. This makes the belly leather a little softer, and stretchier, than from other areas of the hide. While not considered prime leather, belly cut leather can be used for a variety of leather working uses.

Double Belly Leather Cut

The belly cut of a leather hide is from the left and right edges of the hide. The belly of animals naturally expands and contracts as food and water are consumed. This makes the belly leather a little softer, and stretchier, than from other areas of the hide. While not considered prime leather, belly cut leather can be used for a variety of leather working uses.

TYPES OF LEATHER FROM DIFFERENT ANIMAL HIDES

Leather can be produced from the skin of any animal. Throughout history many leathers have been made across times, regions, and through different methods.

The most common today are cow, sheep, goat, and pig. Though, most any type can be obtained if needed for a project. Let’s explore some of the more common, and less common types of leather below.

In general, when speaking about animal leathers, those from larger animals such as cattle are referred to as “hides”. Those from smaller animals such as rabbits or pigs are referred to as skins. Also in terms of volume, cattle leather makes up about 67% of the total annual leather production around the world.

Cattle – Bulls

Bulls are un-castrated male cattle. They have higher levels of testosterone and in general, thick, heavy hides. Bull leather is useful for thicker leather uses such as in heavy belts and show and boot soles. A low ratio number of male cattle are kept as bulls, to reproduce the breeds, so much lower amounts of bull leather are usually available than other types.

Cattle – Steers

Steers are castrated male cattle. They are one of the most popular types of animal leather sought. There are also many more steers kept than bulls, so steer leather is more widely available. It works well for leather applications such as saddlery, belts, some shoes, and other strap items.

Cattle – Cows

Cows are female cattle that have had calves. They are very common, and popular. Cow leather is a thick, soft leather that works well for most common leather needs.

Cattle – Heifers

Heifers are female cows that have not yet had a calf. This type of leather is generally soft and pliable, great for shoes, boots, and other similar leather applications.

Cattle – Dairy Cows

Dairy cows are female cattle that are bred primarily for the production of milk. Their hides are generally soft and thin. This makes it a great leather for lighter belts, wallets, clothing, upholstery, and straps.

Cattle – Calves

Calves are young male or female cattle. Their hides are generally very soft, thin, and supple. This makes it useful for finer leather applications such as wallets, watchbands, and smaller leather accessories including handbags.

Pigs

Pig leather mostly is produced in China. It is used primarily in clothing, due to the breathability and lightness of the skins. Pig leather makes up about 10% of the total leather production around the world.

Sheep

Sheep leather, also called sheep skin, is popular because it often has one side as leather and the other covered in wool. the wool naturally draws perspiration away from the wearer. This makes it an ideal leather for use in year-round seat upholstery, shoes, slippers, boots, and moccasins. Sheep leather, including lamb leather) makes up about 12% of the total leather production around the world.

Goat

Goat leather is a very soft, strong, and durable leather. It is used often in the production of shoes, boots, gloves, rugs, and bags. The skins are supple and flexible, making for a comfortable feel. Goat and kid (young goat) leather makes up about 11% of the total leather production around the world.

Horse

Horse leather is most commonly associated with the premium “cordovan” leather. It is made from the butt section of horses. Cordovan leather is very thick, smooth, and dense. It works excellently for fine shoes and gloves. Also, when compared to cattle hides, horse butts cover a relatively small surface area. This is why cordovan leather products are usually small items such as shoes, gloves, and small accessories.

TYPES OF LEATHER FINISHES-FINISHED LEATHER

When leathers are made, they can be finished in many different ways. These methods yield leathers that can be used for a variety of different purposes. Variations can include texture, flexibility, color, and finish. Let’s explore some of the major types of finished leather.

Aniline Leather

Aniline leather is a type of leather dyed only with soluble dyes. They allow the natural surface of the leather to show through (blemishes, cuts, etc.). Generally only higher quality leathers are used since they have nice, even surfaces.

It is then finished with a thin protective coating to help prevent fast wear of the leather, or any other staying or discoloration from showing up on the surface.This can be a visually appealing dye approach, since it does allow the original surface of the leather to show through.

Semi Aniline Leather

Semi-aniline leather is a type of leather that is dyed only with soluble dyes. It is similar to aniline leather, though it is only slightly pigmented. Semi-aniline leathers allow the natural surface of the leather to show through (blemishes, cuts, etc.).

It is then finished with a thin protective coating to help prevent fast wear of the leather, or any other staying or discoloration from showing up on the surface.Generally only higher quality leathers are used since they have nice, even surfaces. This can be a visually appealing dye approach, since it does allow the original surface of the leather to show through.

Antique Grain Leather

Antique grain is a type of leather that has been treated with a surface affect to give an aged and worn appearance. It might involve several tones of finish, or a rubbed patten to mimic wear over time. Antique grain leather allows one to utilize an aged look in their finished product, without requiring the leather to be very old or worn out.

Bicast Leather

Bicast is a type of leather made with a split leather backing and an embossed/impressed layer of polyurethane or vinyl on the top. This gives the appearance of a patterned/shiny leather, without the cost of a true top or full grain leather piece.

Brush Colored Leather

Brush colored leather is a type of leather that has pigment applied via a brush. This creates a unique pattern of color on each piece. The variations might be in gradient, blending, or overall tone. Bruch colored leather is nice for finished pieces that seek a distinct and creative visual appeal.

Degrained Leather

Degrained leather is a type of leather that has had the grain layer removed. This generally occurs towards the end of the production process. Benefits of degrained leather include a smooth, consistent surface that looks quite nice. However, removing the grain also weakens the outer surface of the layer, making it more susceptible to wear and moisture penetration.

Double Face Leather (Double Sided Leather)

Double face leather, also referred to as double sided leather, is a type of leather that has two uniquely finished sides. Some examples include sheep skins, where one side is finished leather and the other is wool. Another is leather that might have different embossed surfaces, one on each side. It could also relate to color, with each side being a unique color or variation of colors.

Embossed Leather

Embossed leather is a type of leather created by producing raised patterns on the finished hide. This can be done by stamping, pressing, rolling, moulding, or forming the leather. the embossed elements can be designs, lettering, or any visual enhancement to the leather’s surface.

Embroidered Leather

Embroidered leather is a type of leather that has had embroidery applied to it. Embroidery is the craft of embellishing materials with needle and thread. The pattern of the thread is usually placed in such a way as to result in a decorative pattern or motif that is now part of the embroidered material. this is done mainly for visual or aesthetic reasons.

Faux Leather

Faux leather is a type of synthetic leather made generally of polyurethane or vinyl. Faux leather is intended to look like real leather yet cost significantly less. It is used often in the furniture industry and has the benefits of being inexpensive (compared to real leather), durable, and easy to clean.

It does however not reflect real leather qualities such as wearing better over time, having natural stretchability, breathability, and resistance to cuts and other abrasions, and a unique natural look/feel.

Faux leather can be referred to by a number of names, which can include:

- Faux Leather

- PU Leather

- Vinyl Leather

- Vegan Leather

For a detailed look at this type of material, click here for my article about synthetic leather and how it’s made.

Hand Worked Leather

Handworked Leather is a type of leather created by the manual application of leather tools. This can result in leather with tooled, stamped, etched, or embossed surfaces. The results can look quite stunning as the craft of hand working leather is an art in itself.

Interwoven Leather

Interwoven Leather is a type of leather that has been braided together. Often seen in belts, the weave of the leather laces or strips creates a unique looking , textured piece. Weaving leather can be used for straps or belts, as well as small bags and pouches, depending on the skill of the weaver.

Metallic Leather

Metallic Leather is a type of leather that has had a metal layer of material added to it during the finishing process. This layer creates a metallic, shiny, reflective look to the finished leather. It provides a finishing option that is most often used in clothing, accessories, and handbags.

Nappa (Napa)

Napa is type of leather this is more a general marketing term for a soft, smooth, full grain leather. Some napa comes from genuine leather and isn’t the highest of quality; the term itself isn’t a clear identifier of quality or material. Moreso, it can be used to connote a smooth, soft leather. The history and more details on nubck are available in my Napa leather article here.

Nubuck Leather

Nubuck is a type of leather that is a top-grain leather that has has the surface sanded in such a way as to leave the surface with a slight nap of short protein fibers. This produces a soft, velvet-like surface that is pleasing to touch, and also has a unique visual appearance. Nubuck leather is often used in jackets, gloves, and accessories. More details are available in my nubuck-specific article here.

Oil Leather (Pull-Up Leather, Waxy Leather, Waxed Leather)

Oil Leather, also known as pull-up leather, waxy leather, and waxed leather, is a type of leather that has a larger volume than average amount of oils and waxes in the surface finish. When the leather pieces are flexed and moved, the surface catches the light in different ways, do to the reflections on the oils and waxes. This provides for a varied look across surface tones, which could be quite visually appealing.

Patent Leather

Patent leather is a type of leather that has a high-gloss finish applied via a coating, generally linseed oil. It was developed in 1818 (by inventor Seth Boyden in Newark, New Jersey). Patent leather finishing is often very noticeable with a highly-reflective finish. More modern patent leather replaces the linseed oil finish with a plastic coating finish. Click here for my detailed article on patent leather.

Pearlized Leather

Pearlized Leather is a type of leather that has had a liquid layer of color added to the surface during finishing. It provides for a soft, subtle shine and reflection to the leather. While not as reflective as metallic leather, pearlized leather is a subtler implementation of the same concept. It is popularly used on clothing, accessories, and handbags.

Pigmented Leather

Pigmented leather is a type of leather that is finished with a top coat of pigment (or paint). That pigment helps both provide an even surface on the leather, and also a protective coating. Pigmented leather is often coated with a clear protective sealer, to help protect the pigment layer.

Printed Leather

Printed Leather is a type of leather that has has the surface texture printer, to stamped into it. This creates various leather surface types that might serve both functional and aesthetic purposed. Functional purposes might include helping make the leather surface more scratch and abrasion resistant. Aesthetic purposes might include making it look uniformly pebbled or nubbed. The textures of printed leathers can feel preferable as well. Saffiano leather is an example of a printed leather. For a deeper look into pebbled leather, click here to check out my article with more details.

Quilon Leather

Quilon is a tyle of leather produced by the Doc Martens footwear comapny. It is a unique style of smooth leather that is finished with a “haircell” pattern; a fine, textured print that gives the surface a stylish look. Quilon leather was developed in 2007, based on the now-vintage Doc Marten leather from the 1970s. For a detailed look, click here for my article about quilon leather.

Stretch Leather

Stretch Leather is a type of leather that is usually a composite leather made to be able to stretch when used. It can use a processed leather surface mixed with a synthetic under layer that allows the material to stretch yet still retain a uniform look with most of the usual performance qualities. Stretch leathers are often used in clothing and leather goods that will be worn and flex with human movement.

Suede Leather

Suede is a type of leather made using a similar approach as Nubuck, where the surface is sanded in such a way as to leave the surface with a slight nap of short protein fibers. Though, instead of being made from full grain leather, suede is made from split grain leather. Here is my article that dives deeply into suede.

Washable Leather

Washable Leather is a type of leather that is better suited to cleaning. While leather should not be roughly cleaned often (and likely shouldn’t if well-cared for), special leather washing methods are available. For items that have an expected use requiring frequent cleaning, such as some clothes, a washable leather can be used to help ensure the items last longer and stay in great shape.

There are so many types of leather available, suitable for a range of needs. If you’re curious what thicknesses of leather would work well for your next project, click here to read my guide on leather weights. Depending on the type of project you’re working on, or preference for leather qualities, you’ll likely find a great leather that will help make some incredible leather goods.